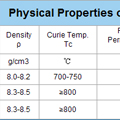

AlNiCo Magnet is mainly consist of Aluminum, Nickel, Cobalt, They represent the most versatile magnet material available. The range of properties can be accurately designed for specific applications by changes to element analysis and heat treatment. They are widely used in Magnetos, Separators , MRI , Sensors , Holding magnets ,Security systems ,Relays

Machining and tolerances Machining and tolerances

Most alnico magnets are manufactured using typical foundry casting techniques, where the molten alloy is poured into sand molds. Very small magnets, usually one ounce or less, are also produced using the press and sinter techniques. Alnico is hard and brittle (45-55 Rockwell C), and is not suitable for drilling, tapping or conventional machining operations. Close tolerances are attained by abrasive grinding and cutting. Standard tolerances for ground dimensions are +/-.005". Tolerances for as cast dimensions vary with the actual part size. Un-ground surfaces are gray to dark brown in color but are bright metallic after grinding.

Temperature constraints and methods of magnetization

Alnico has the lowest temperature coefficient of any commercial magnet material, providing for excellent stability over a wide temperature range. A properly designed circuit usings alnico magnets will have a stable flux output during temperature fluctuations. Maximum operating temperature for alnico is 950°F.

Alnico magnets can be partially demagnetized if like poles of magnets are brought together. Placing individual magnets in contact with ferrous materials can also partially demagnetize them. Care must be exhibited in handling magnetized magnets. Typical alnico 5 applications require a long magnetic length to pole surface ratio (usually 4:1 or greater) to insure good magnetic performance.

|

Machining and tolerances

Machining and tolerances